Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

On The Testing And Strength Of Railway Materials, &C.

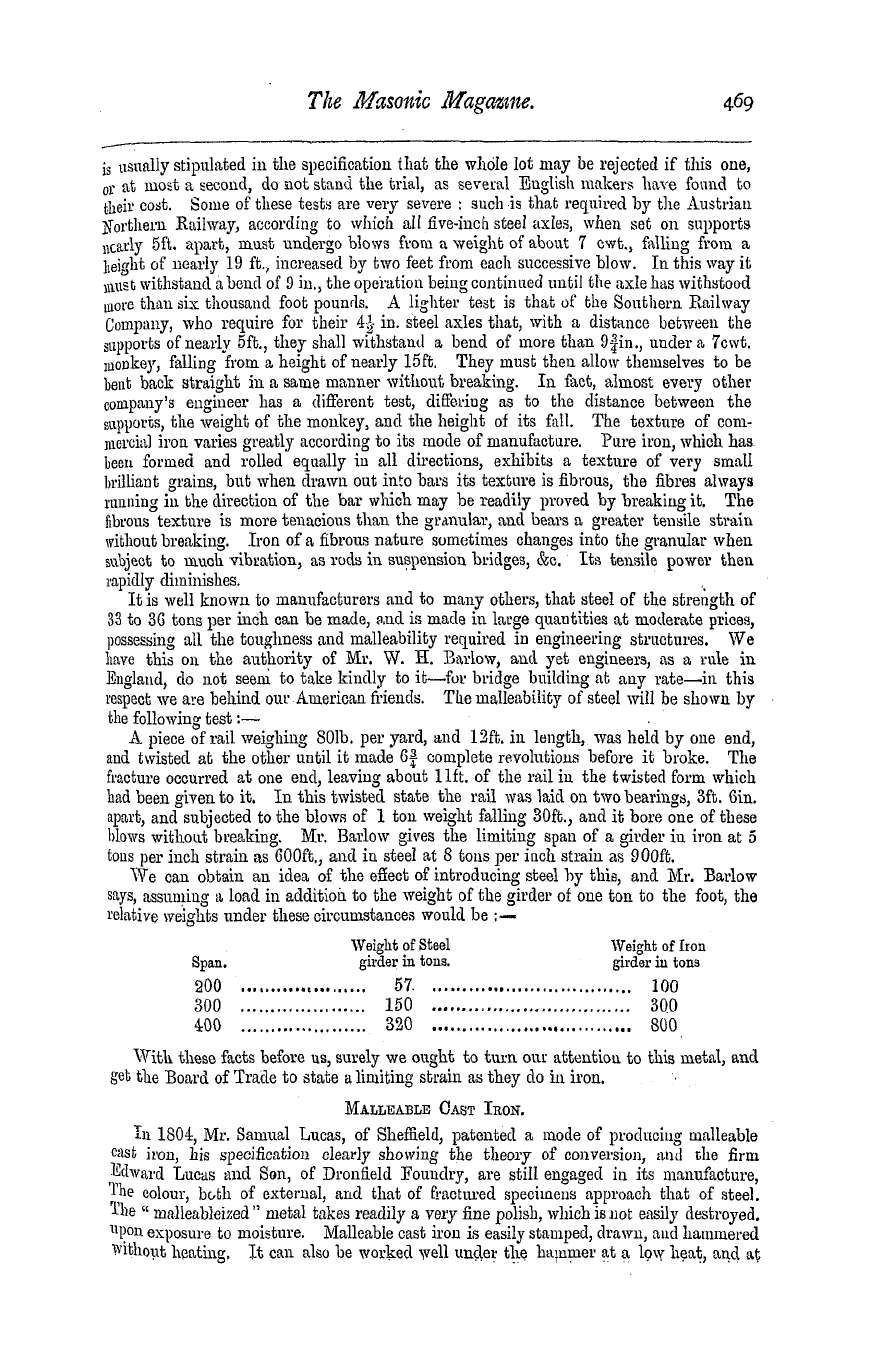

tempering , are greater when the quantity of carbon is considerable , yet it acts more oi less in the mild quahties of steel , so that we cannot rely entirely on the aid of the chemist , but must fall back on mechanical tests , which proves not only the material , but the Avorkmanship . The rolling weight test is made by heavy rollers fixed in a framework and radial bars connected to a centre boss , after the form of a turn-table ; motion is imparted to a centre vertical shaft by means of shafting and wheels underneath , which is

driven by steam power . It can be made with or without springs ; ivithout springs the tost is more severe , but by using springs the rollers may be lightened and greater Aveight throAvn into tho frame . The rails to be tested are formed into a circle or polygon , supported on sleepers , packed with ballast in the usual manner . If the rails are bent into a circular form , Mr . Price , the patentee , says , hi his experience the texture of the iron is of no moment

—provided the rails are bent at a dull red heat—but they may be arranged as a polygon , which plau possesses the collateral advantage that the rollers ivear more evenly over their entire surface . These rails are tested by a dead weight produced by hydraulic pressure . A piece of the rail is placed upon 5 ft . bearings , and a slig htly curved iron surface , 3 f in . in width , is made to press upon the centre of the rail . The test is , that , under these conditons , a pressure of 40 , 0001 b . shall not deflect the centre of the rail more than one inch ] also , that 60 , 0001 b . shall deflect it 9 in . ivithout breaking it .

TEST FOR IKON RAILS , 751 b . per yard . 1 st Test . —Each of these rails placed on two supports , 3 ft . Sin . apart , must carry for five minutes in the centre , between points of support , a hanging weight of 12 tons , deflection 015 in . as a maximum , and when the weight has been taken off , the permanent set must not be more than 0 ' 04 in ., or 1 millimetre , and on condition that , at the second placing of the same wei ght , the deflection does not incraase more than l-150 in . or 1-5 millimetre .

2 nd Test . —Each rail in the same position must carry also for five minutes , without breaking , a weight of 30 tons , then , having nicked the surface of the head , it shall be tested to breaking by the bloivs of a tup 6481 b ., weight falling 18 ft . ; ancl the fracture must show a combination of iron conforming to aforesaid condition . 3 rd Test . —Each of the two halves of broken rail placed on the supports , 3 ft . Sin . apart , shall be tested by the blows from a tup 6481 b ., falling 7 ft ., on the centre"betiveen the point of supportunder this testthe rail bendbut must not show sigu

; , may , any of destruction . The Vignoles section of rail Avould seem to have some advantage over the double head , as the bottom flange is placed at a greater distance from the neutral axis , besides resisting side-strains and torsions ; and , as a matter of practice , none but ductile tough iron can be rolled into a wide flange . But this section of rail cannot be rolaid ivith such facility as the double head shape .

TESTING OF FISH PLATES FOR RAILS . 1 . Six fish plates to be taken at random from one day ' s rolling , and bent to an angle ° f 60 cleg , without any sign of fracture . 2 . Holes to be punched at a distance from the edge equal to the diameter of hole , without bulging the metal at sides .

WEAKENING RAILS BY DRILLING AND PUNCHING . An experiment is mentioned by Hackney in his " Manufacture of Steel" : — 1 . A piece of rail with no holes in it stood a blow of 1 ton falling 20 ft . ¦ > . Piece of same rail ivith a punched hole through the web , broke under first blow ftt a 3 ft . M . ° ' 3 . A piece ivith a drilled hole same size , while it stood the first blow at 2 ft . fall . b » ke ivith the 2 nd at 4 ft . 2 G 2

Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

On The Testing And Strength Of Railway Materials, &C.

tempering , are greater when the quantity of carbon is considerable , yet it acts more oi less in the mild quahties of steel , so that we cannot rely entirely on the aid of the chemist , but must fall back on mechanical tests , which proves not only the material , but the Avorkmanship . The rolling weight test is made by heavy rollers fixed in a framework and radial bars connected to a centre boss , after the form of a turn-table ; motion is imparted to a centre vertical shaft by means of shafting and wheels underneath , which is

driven by steam power . It can be made with or without springs ; ivithout springs the tost is more severe , but by using springs the rollers may be lightened and greater Aveight throAvn into tho frame . The rails to be tested are formed into a circle or polygon , supported on sleepers , packed with ballast in the usual manner . If the rails are bent into a circular form , Mr . Price , the patentee , says , hi his experience the texture of the iron is of no moment

—provided the rails are bent at a dull red heat—but they may be arranged as a polygon , which plau possesses the collateral advantage that the rollers ivear more evenly over their entire surface . These rails are tested by a dead weight produced by hydraulic pressure . A piece of the rail is placed upon 5 ft . bearings , and a slig htly curved iron surface , 3 f in . in width , is made to press upon the centre of the rail . The test is , that , under these conditons , a pressure of 40 , 0001 b . shall not deflect the centre of the rail more than one inch ] also , that 60 , 0001 b . shall deflect it 9 in . ivithout breaking it .

TEST FOR IKON RAILS , 751 b . per yard . 1 st Test . —Each of these rails placed on two supports , 3 ft . Sin . apart , must carry for five minutes in the centre , between points of support , a hanging weight of 12 tons , deflection 015 in . as a maximum , and when the weight has been taken off , the permanent set must not be more than 0 ' 04 in ., or 1 millimetre , and on condition that , at the second placing of the same wei ght , the deflection does not incraase more than l-150 in . or 1-5 millimetre .

2 nd Test . —Each rail in the same position must carry also for five minutes , without breaking , a weight of 30 tons , then , having nicked the surface of the head , it shall be tested to breaking by the bloivs of a tup 6481 b ., weight falling 18 ft . ; ancl the fracture must show a combination of iron conforming to aforesaid condition . 3 rd Test . —Each of the two halves of broken rail placed on the supports , 3 ft . Sin . apart , shall be tested by the blows from a tup 6481 b ., falling 7 ft ., on the centre"betiveen the point of supportunder this testthe rail bendbut must not show sigu

; , may , any of destruction . The Vignoles section of rail Avould seem to have some advantage over the double head , as the bottom flange is placed at a greater distance from the neutral axis , besides resisting side-strains and torsions ; and , as a matter of practice , none but ductile tough iron can be rolled into a wide flange . But this section of rail cannot be rolaid ivith such facility as the double head shape .

TESTING OF FISH PLATES FOR RAILS . 1 . Six fish plates to be taken at random from one day ' s rolling , and bent to an angle ° f 60 cleg , without any sign of fracture . 2 . Holes to be punched at a distance from the edge equal to the diameter of hole , without bulging the metal at sides .

WEAKENING RAILS BY DRILLING AND PUNCHING . An experiment is mentioned by Hackney in his " Manufacture of Steel" : — 1 . A piece of rail with no holes in it stood a blow of 1 ton falling 20 ft . ¦ > . Piece of same rail ivith a punched hole through the web , broke under first blow ftt a 3 ft . M . ° ' 3 . A piece ivith a drilled hole same size , while it stood the first blow at 2 ft . fall . b » ke ivith the 2 nd at 4 ft . 2 G 2