Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

Die Engraving, Sinking, And Multiplying. By Mr. J. Newton, Royal Mint.

covering them with animal charcoal and depositing the whole for twenty-four hours in an oven heated by coke ; they are afterwards withdrawn , removed from the pot , ancl allowed to cool gradually . Next they are taken to the lathe and one end of each is turned . That which is intended to become the " matrix" die ( of which more anon ) is made perfectly flat and smooth , and it is upon this prepared surface that the artists' talent will have to be first expended . The second block , turned

slightly conical , and which is destined to become the " puncheon " may be put out of view pro tern . The engraver addresses himself to . the work of etching in upon the matrix block his approved design , say of the obverse for tbe florin . Assured of having put in his outlines correctly , the work of engraving fairly commences , and only those who have witnessed the operation of die cutting can realise the amount of patience and skill necessary for its successful completion . After many weeks of close and constant

application the design in intaglio will probably be finished , repeated impressions in clay and soft metal being taken adinterim by the artist as tests of the accuracy of his work . Innumerable touchings ancl re-touchings , with the graver , are indispensable to the minute realisation of the design , bufc it at last satisfactorily appears on tbe surface of the softened steel . The letters to form tbe legend and the date are stamped in by aid of punchesancl the matrixor first dieis engraven . A

, , , very important , ancl to the engraver , an anxious operation follows . It is thafc of hardening the matrix . In its present annealed condition it is practically useless , and , therefore , the risk must be run of exposing a very beautiful work of arfc in quick succession to the tender mercies of tlie antagonistic elements fire and water . There is no escaping this , however ; and the artist , if a nervous man , may tremble for the result . His only hope lies

in the excessive care with which the work is clone , ancl the excellence of tlie cast steel of which the die is composed . The preservation unmarreel of the delicate lines ancl tracery which have cost him so many hours and so much exertion is naturally a great consideration . To ensure this , as far as possible , the engraved face of the die is covered by a mask composed of some fixed oil , thickened to the consistency of a paste by the addition of animal charcoal finely powdered . This Ethiopian-like compound is spread over the surface of the engraving to which it closely adheres , filling all interstices .

As an extra precaution an iron ring is usually made to encompass tightly the matrix before hardening , so as to lessen the risk of fracture . In this condition it is deposited with its face downwards in a pot or crucible and buried once more in animal charcoal , i . e ., burnt leather , horn , & c . Tlie crucible ancl its precious contents are placed now in a furnace , the whole being heated to redness . After submission to this saturation of fire , if the term be admissible , for about an hour the pot is

withdrawn ancl the matrix , taken out of it by means of a pair of tongs is instantly and sans ceremonie plunged into a cold water bath . The bath is sufficiently capacious to contain as much water as will ' prevent the water becoming sensibly warm , by the immersion of the red hot die . Held firmly by the workman's tongs , the matrix is swayed to and fro rapidly in the water until it ceases to splutter and hiss at its rough treatment . Should no unusual or singing sound proceed from it while in

the bath , the probability is that the expansion induced by the Are , and the sudden contraction caused by the cold water have not injured the . die , and the engraver may take heart again , for his work is ' safe ancl sound . If , on the contrary , it sings , the die will be found to have cracked in the process of hardening and his work will have to be done over again . For the reasons previously given such a disastrous result seldom happens at the Royal Mint .

Allowing that all has proved favourable , the coating which protects the engraved surface is removed , ancl the matrix is forwarded to the polisher , who by pressing its "table , " or face , carefully against a flat disc of iron running rapidly in a lathe , and upon which a film of flower emery and oil has been spread , soon produces a mirror-like polish . Tempering is the next operation , for at present the steel is much too hard for its purposeand tin ' s is effected by putting the matrix into water to

, be gradually heated to the boiling point or placing it on a bar of hot iron . In either case the work is done when the die , after a series of chameleon-like changes of colour , assumes that of pale straw . At this juncture , therefore , it is again plunged into cold water , ancl the obverse matrix is ready for use . Arrangements of a precisely similar character throughout are observed in the production of the reverse matrix , and thus the first

and more important stage in the manufacture of coining dies is passed . It is time that we turned to the second block of steel , namely , that intended for the " puncheon . " This has been annealed ancl turned , not flat , but flatly conical , OH the surface to be decorated . Both it and the matrix are thus made ready for " the press , " not a printing press , but a massive ancl powerful stamping

press , with a coarse triple threaded screw of some Gin . in diameter passed vertically through its centre . Attached to theupper part of the screw , and above the press are two heavily weighted fly arms which constantly tend to force down the screw-To the lower end of the screw , and with its face downwards , the matrix is firmly fixed by a workman , who stands in a recess sunk in the floor to a depth convenient for bringing his eyes ancl his hands to a level with the bed of the press .

The puncheon block is deposited next with its face turned upwards , on the solid cast iron bed of the press , and immediately and fairly below the matrix . All being ready , several strongarmed workmen seize tbe fly arms , and walking round with them raise the screw and matrix until the latter is several inches above the puncheon block . On a sudden they release their hold andthe weihted arms revolving with a speed and force which would

g be fatal to any person standing in their way , drive down the matrix until it impinges with a dull , heavy thud upon the puncheon block . Again the workmen stand to their ( fly ) arms and raise the screw of the press . The effect of the blow is then , seen in the depressed apex of the cone-topped die which received its impact , and in the transference to itself thereby of a partial in relief of the intaglio engraved matrix . The compression

copy of the particles of steel composing the puncheon by the stress of the blow , mechanically hardens the puncheon , and before its impression can be completed by a repetition of the act , it must , be again annealed . This is effected in the same way as before . The puncheon is returned to the press , and the matrix , now de taehed from the screw , is placed loosely on the top of it , though , for an obvious reason , in such a way as that tlie engraving on

tho matrix and the partly finished impression on the puncheon , shall exactly match or fit each other . A blank block of steel is then affixed firmly by aid of set screws to the place before tenanted by the matrix , and may be saicl to represent a hammer , for it will

presently descend with great force upon the matrix , lhe fly arms are turned backward by the workmen , the . press screw is- , raised , tlie arms released , and , gathering momentum as they revolve , the hammer block is made to fall heavily ou the matrix-The effect of this second blow will , perhaps , be to make the transfer of the engraving as complete on the puncheon as is that of a seal pressed by the hand upon molten sealing wax , or it may be , if tlie steel is very obstinate , that another annealing and .

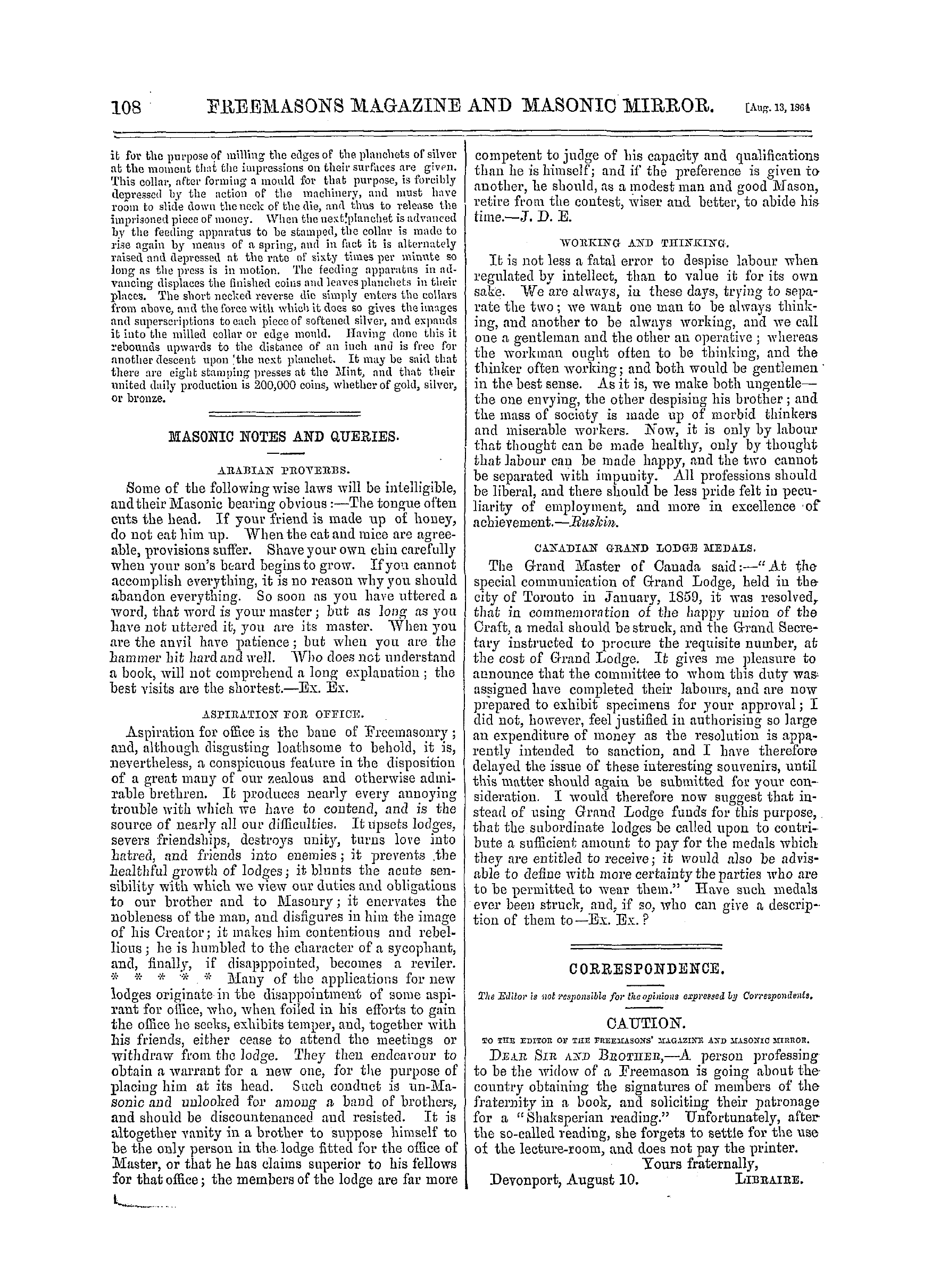

another blow may be required to effect that object . Eventually at least the puncheon will be found upon examination to have imbibed an exact ancl faithful copy in relief of the engraver ' s work on the matrix to the finest line and most minute point of detail . The duty of this latter is now done , at all events for the present , and it is placed in the engraver ' s closet . Far otherwise is ifc with the puncheon , ( or its mission is about to commence It is therefore hardened and tempered ; polished it cannot be ,

, on account of its raised surface , and then returned to the press . Such are tlie processes pursued in the making of matrices and . puncheons in reference both to coining ancl medal-striking—for . obverse and reverse , although , from the bold impressions usual on medals , many more annealings ancl sinkings of the puncheons are necessary than of those used for coin . Confining our . attention for the sake of brevity to the florin , let it now be .

presumed that puncheons for its obverse and reverse have been successfully prepared , it remains to be shown how they are put . into useful requisition , and how tbey are made the parents of rapidly-multiplying families of coining dies . Florin bars of cast , steel are about 10 ft . long , 1 Jin . broad , and 1 jin . thick ; upon these the Mint blacksmith is the first operator . One at a time they are conveyed to the forge , and out , while hot , into short , pieces of If in . in length , and in this form , therefore , resemble

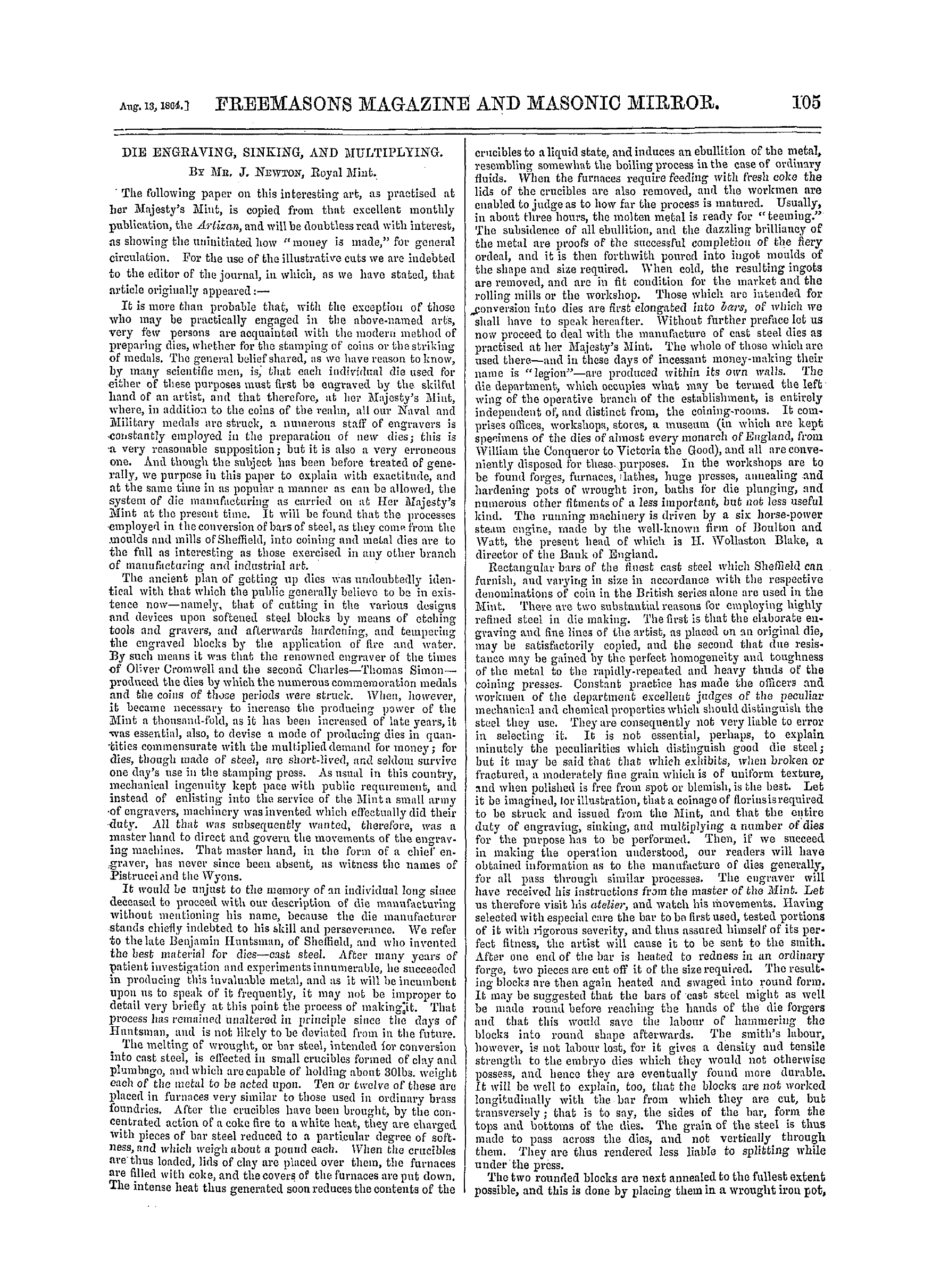

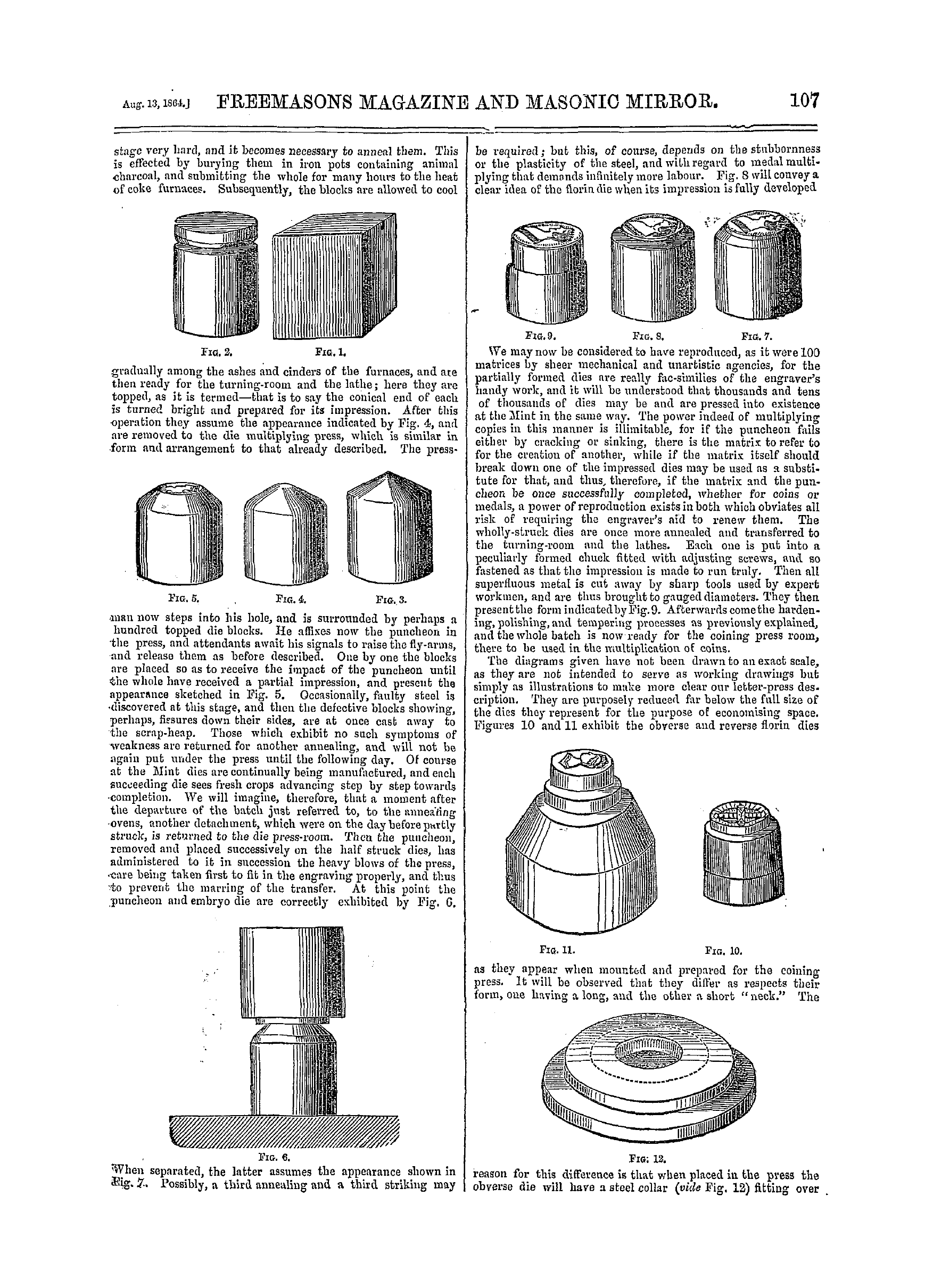

Fig . 1 . These square or rectangular blocks he next proceeds to hammer into a cylindrical form , as shown in Fig . 2 . He then cuts off in a slanting direction one end of each of the die blocks , and shapes them , by way of preparation for the lathe ,, and thus they take tbe appearance depicted in Fig . 3 . Thus he proceeds with die block after die block until he has accumulated a large quantity and diminished materially the length of the bar off which they have been cut . Owing to the severe hammering to which they have been subjected , they are at this ,

Note: This text has been automatically extracted via Optical Character Recognition (OCR) software.

Die Engraving, Sinking, And Multiplying. By Mr. J. Newton, Royal Mint.

covering them with animal charcoal and depositing the whole for twenty-four hours in an oven heated by coke ; they are afterwards withdrawn , removed from the pot , ancl allowed to cool gradually . Next they are taken to the lathe and one end of each is turned . That which is intended to become the " matrix" die ( of which more anon ) is made perfectly flat and smooth , and it is upon this prepared surface that the artists' talent will have to be first expended . The second block , turned

slightly conical , and which is destined to become the " puncheon " may be put out of view pro tern . The engraver addresses himself to . the work of etching in upon the matrix block his approved design , say of the obverse for tbe florin . Assured of having put in his outlines correctly , the work of engraving fairly commences , and only those who have witnessed the operation of die cutting can realise the amount of patience and skill necessary for its successful completion . After many weeks of close and constant

application the design in intaglio will probably be finished , repeated impressions in clay and soft metal being taken adinterim by the artist as tests of the accuracy of his work . Innumerable touchings ancl re-touchings , with the graver , are indispensable to the minute realisation of the design , bufc it at last satisfactorily appears on tbe surface of the softened steel . The letters to form tbe legend and the date are stamped in by aid of punchesancl the matrixor first dieis engraven . A

, , , very important , ancl to the engraver , an anxious operation follows . It is thafc of hardening the matrix . In its present annealed condition it is practically useless , and , therefore , the risk must be run of exposing a very beautiful work of arfc in quick succession to the tender mercies of tlie antagonistic elements fire and water . There is no escaping this , however ; and the artist , if a nervous man , may tremble for the result . His only hope lies

in the excessive care with which the work is clone , ancl the excellence of tlie cast steel of which the die is composed . The preservation unmarreel of the delicate lines ancl tracery which have cost him so many hours and so much exertion is naturally a great consideration . To ensure this , as far as possible , the engraved face of the die is covered by a mask composed of some fixed oil , thickened to the consistency of a paste by the addition of animal charcoal finely powdered . This Ethiopian-like compound is spread over the surface of the engraving to which it closely adheres , filling all interstices .

As an extra precaution an iron ring is usually made to encompass tightly the matrix before hardening , so as to lessen the risk of fracture . In this condition it is deposited with its face downwards in a pot or crucible and buried once more in animal charcoal , i . e ., burnt leather , horn , & c . Tlie crucible ancl its precious contents are placed now in a furnace , the whole being heated to redness . After submission to this saturation of fire , if the term be admissible , for about an hour the pot is

withdrawn ancl the matrix , taken out of it by means of a pair of tongs is instantly and sans ceremonie plunged into a cold water bath . The bath is sufficiently capacious to contain as much water as will ' prevent the water becoming sensibly warm , by the immersion of the red hot die . Held firmly by the workman's tongs , the matrix is swayed to and fro rapidly in the water until it ceases to splutter and hiss at its rough treatment . Should no unusual or singing sound proceed from it while in

the bath , the probability is that the expansion induced by the Are , and the sudden contraction caused by the cold water have not injured the . die , and the engraver may take heart again , for his work is ' safe ancl sound . If , on the contrary , it sings , the die will be found to have cracked in the process of hardening and his work will have to be done over again . For the reasons previously given such a disastrous result seldom happens at the Royal Mint .

Allowing that all has proved favourable , the coating which protects the engraved surface is removed , ancl the matrix is forwarded to the polisher , who by pressing its "table , " or face , carefully against a flat disc of iron running rapidly in a lathe , and upon which a film of flower emery and oil has been spread , soon produces a mirror-like polish . Tempering is the next operation , for at present the steel is much too hard for its purposeand tin ' s is effected by putting the matrix into water to

, be gradually heated to the boiling point or placing it on a bar of hot iron . In either case the work is done when the die , after a series of chameleon-like changes of colour , assumes that of pale straw . At this juncture , therefore , it is again plunged into cold water , ancl the obverse matrix is ready for use . Arrangements of a precisely similar character throughout are observed in the production of the reverse matrix , and thus the first

and more important stage in the manufacture of coining dies is passed . It is time that we turned to the second block of steel , namely , that intended for the " puncheon . " This has been annealed ancl turned , not flat , but flatly conical , OH the surface to be decorated . Both it and the matrix are thus made ready for " the press , " not a printing press , but a massive ancl powerful stamping

press , with a coarse triple threaded screw of some Gin . in diameter passed vertically through its centre . Attached to theupper part of the screw , and above the press are two heavily weighted fly arms which constantly tend to force down the screw-To the lower end of the screw , and with its face downwards , the matrix is firmly fixed by a workman , who stands in a recess sunk in the floor to a depth convenient for bringing his eyes ancl his hands to a level with the bed of the press .

The puncheon block is deposited next with its face turned upwards , on the solid cast iron bed of the press , and immediately and fairly below the matrix . All being ready , several strongarmed workmen seize tbe fly arms , and walking round with them raise the screw and matrix until the latter is several inches above the puncheon block . On a sudden they release their hold andthe weihted arms revolving with a speed and force which would

g be fatal to any person standing in their way , drive down the matrix until it impinges with a dull , heavy thud upon the puncheon block . Again the workmen stand to their ( fly ) arms and raise the screw of the press . The effect of the blow is then , seen in the depressed apex of the cone-topped die which received its impact , and in the transference to itself thereby of a partial in relief of the intaglio engraved matrix . The compression

copy of the particles of steel composing the puncheon by the stress of the blow , mechanically hardens the puncheon , and before its impression can be completed by a repetition of the act , it must , be again annealed . This is effected in the same way as before . The puncheon is returned to the press , and the matrix , now de taehed from the screw , is placed loosely on the top of it , though , for an obvious reason , in such a way as that tlie engraving on

tho matrix and the partly finished impression on the puncheon , shall exactly match or fit each other . A blank block of steel is then affixed firmly by aid of set screws to the place before tenanted by the matrix , and may be saicl to represent a hammer , for it will

presently descend with great force upon the matrix , lhe fly arms are turned backward by the workmen , the . press screw is- , raised , tlie arms released , and , gathering momentum as they revolve , the hammer block is made to fall heavily ou the matrix-The effect of this second blow will , perhaps , be to make the transfer of the engraving as complete on the puncheon as is that of a seal pressed by the hand upon molten sealing wax , or it may be , if tlie steel is very obstinate , that another annealing and .

another blow may be required to effect that object . Eventually at least the puncheon will be found upon examination to have imbibed an exact ancl faithful copy in relief of the engraver ' s work on the matrix to the finest line and most minute point of detail . The duty of this latter is now done , at all events for the present , and it is placed in the engraver ' s closet . Far otherwise is ifc with the puncheon , ( or its mission is about to commence It is therefore hardened and tempered ; polished it cannot be ,

, on account of its raised surface , and then returned to the press . Such are tlie processes pursued in the making of matrices and . puncheons in reference both to coining ancl medal-striking—for . obverse and reverse , although , from the bold impressions usual on medals , many more annealings ancl sinkings of the puncheons are necessary than of those used for coin . Confining our . attention for the sake of brevity to the florin , let it now be .

presumed that puncheons for its obverse and reverse have been successfully prepared , it remains to be shown how they are put . into useful requisition , and how tbey are made the parents of rapidly-multiplying families of coining dies . Florin bars of cast , steel are about 10 ft . long , 1 Jin . broad , and 1 jin . thick ; upon these the Mint blacksmith is the first operator . One at a time they are conveyed to the forge , and out , while hot , into short , pieces of If in . in length , and in this form , therefore , resemble

Fig . 1 . These square or rectangular blocks he next proceeds to hammer into a cylindrical form , as shown in Fig . 2 . He then cuts off in a slanting direction one end of each of the die blocks , and shapes them , by way of preparation for the lathe ,, and thus they take tbe appearance depicted in Fig . 3 . Thus he proceeds with die block after die block until he has accumulated a large quantity and diminished materially the length of the bar off which they have been cut . Owing to the severe hammering to which they have been subjected , they are at this ,